You have no items in your shopping cart.

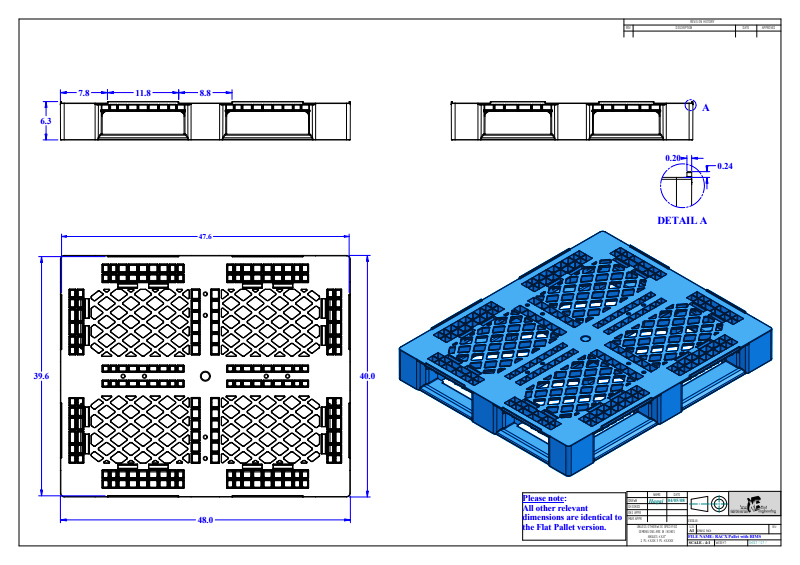

The blueprint to your

perfect pallet is here.

Our pallet experts know exactly what you need.

Contact us for your free pallet consultation.

Get a Quote

Why Plastic?

- Lightweight Wood Pallets: 30-70lbs, Plastic Pallets: As light as 12lbs

- 100% Sustainability Made from recycled resin & can be recycled

- Extremely tough and durable Lasts up to 10X longer than wood

- Safer for Workers No splinters, nails, or broken pieces of wood

- Sanitary Will not absorb water, dirt, or pathogens. Can be steam cleaned

- Aesthetics Plastic pallets show your company cares about quality

Frequently Asked Questions

- Q

- What is your delivery time?

- A

Most pallets ship the following business day after you place your order and deliver in 2-5 business days (depending on your location).

From the Blog

Pallet Size By Industry

Nov 21, 2016 by Robin Kiefer

What Pallet Size is right for my business?

Choosing the correct pallet size for your warehouse or industry is simple with our easy-to-understand pallet sizing guide.

But do they make a pallet size for my application? Yes! Read on to learn more about about how other markets have helped solved their material handling challenges.

Why One Way?

We Ship Worldwide From Over 15 Locations

Most of our products are in stock, will ship next day, and arrive in 2-5 days depending on your location. In addition, we can ship any size ocean container to any major port globally.Avoid the Hassles of ISPM-15 Documents and Requirements

All of our products are fully export compliant and not subject to the ISPM-15 regulations. Don’t worry about getting cross docked or delayed, ship on plastic and sit back and relax.You Are Our #1 Priority

Our products are cutting edge, but our customer service is old school. You will never have to listen to voicemail, you will always speak to an expert when you call, and if you need us on-site, we’re on the way. Our products can last over a decade so our customer service never expires. You have come to our website, an excellent resource, but you will deal with professional and experienced team members whether you purchase from us or not.

Best sellersss

Privacy Policy

Copyright ©

One Way Solutions

Shop by Category

Shop by Category

Nestable Pallets

Nestable Pallets

Rackable Pallets

Rackable Pallets

Stackable Pallets

Stackable Pallets

FDA Approved Pallets

FDA Approved Pallets

Fire Retardant Pallets

Fire Retardant Pallets

Custom Plastic Pallets

Custom Plastic Pallets

Automotive Pallets

Automotive Pallets

Beverage Pallets

Beverage Pallets

Can Pallets

Can Pallets

Drum & Spill Pallets

Drum & Spill Pallets

Air Freight Pallets

Air Freight Pallets

Pharmaceutical Pallets

Pharmaceutical Pallets